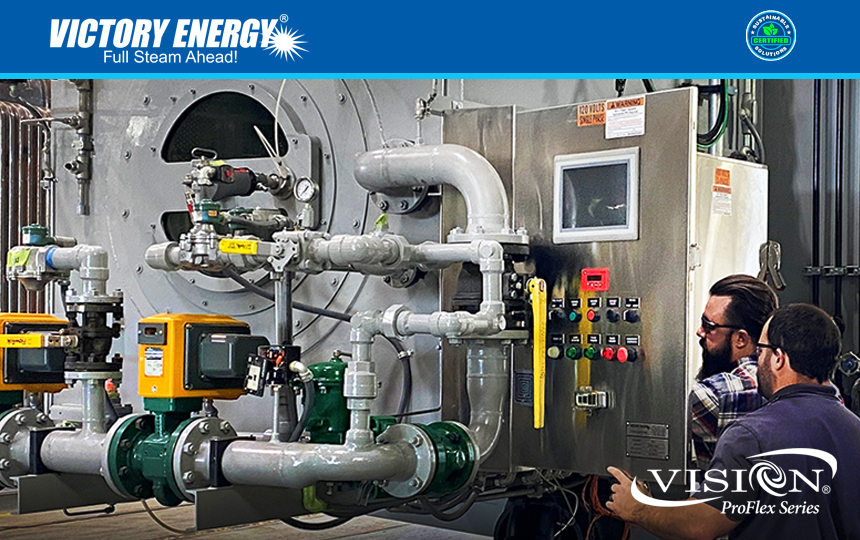

SINGLE-SOURCE SOLUTIONS

Victory Energy’s ability to design, engineer, manufacture and integrate the combustion systems in combination with the steam generation requirements are unique. The benefits of working with a single source for the entire burner and boiler system will enhance efficiencies and maintenance practices.

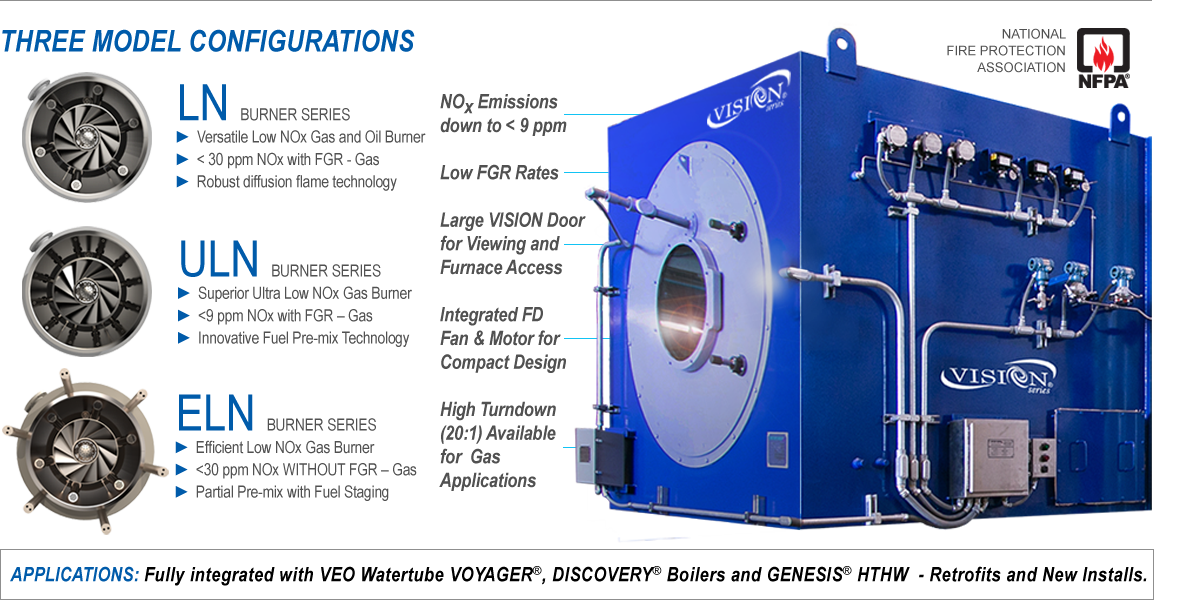

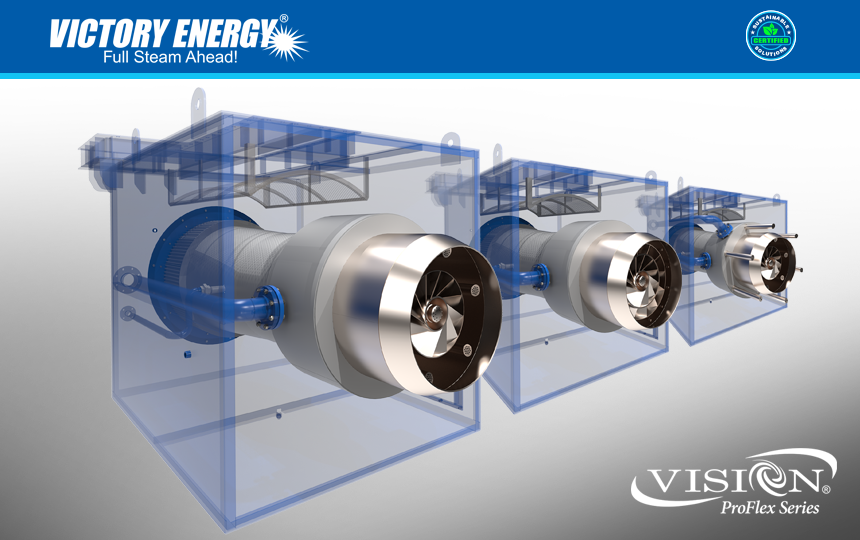

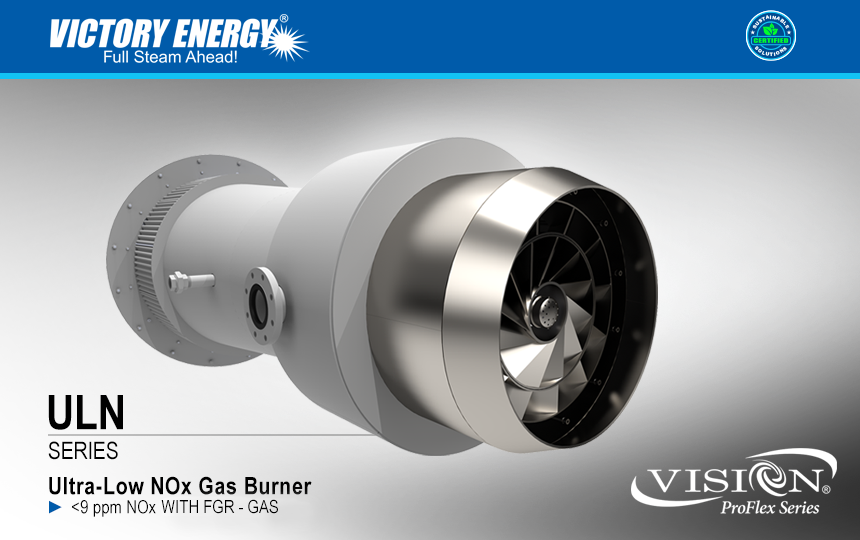

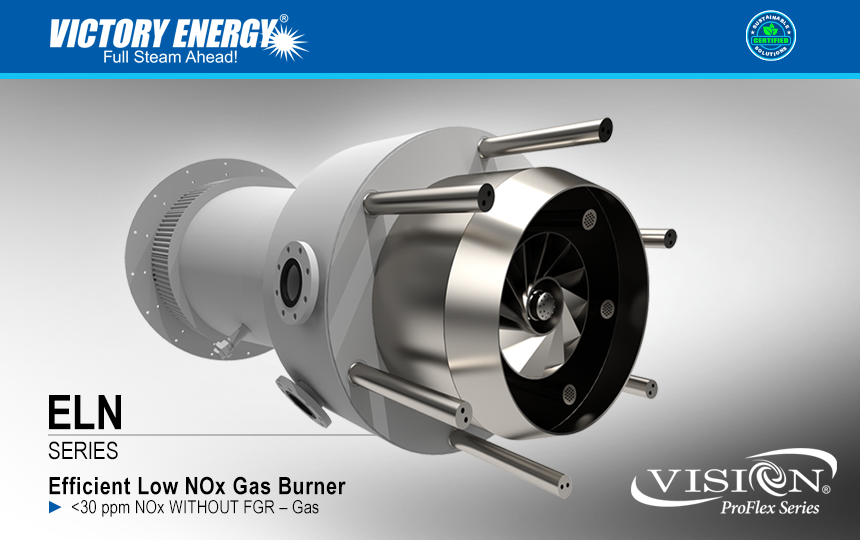

VISION® ProFlex industrial burners provide the best emissions reduction metrics. They’re an integral component of the Victory Energy Sustainable Solutions promise. The product line is comprised of 6 model sizes that deliver the widest range of low NOx emissions performance to meet the most stringent sustainability application challenges.

The complete line of VISION ProFlex burners combined with the proven line of Victory Energy industrial boilers and hot water generators deliver a vertically integrated package that is unmatched in the boiler industry.

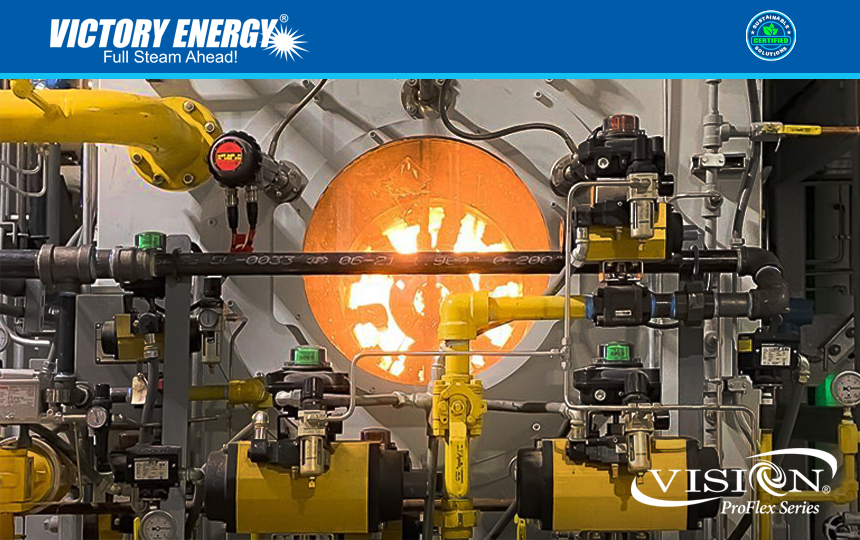

The VISION Burner technology ensures complete and efficient combustion with very low emissions; < 30 ppm NOx with little or no FGR. This sturdy and simple design translates into high reliability and low maintenance. The VISION ProFlex Series Burner can be applied to both single and multi-burner boilers.

Numerical fluid flow simulation tools were used during the design of the VISION ProFlex Series Burner , allowing the traditional windbox to be replaced by strategically placed baffles and openings between the fan and the burner throat, making the burner very compact and efficient.

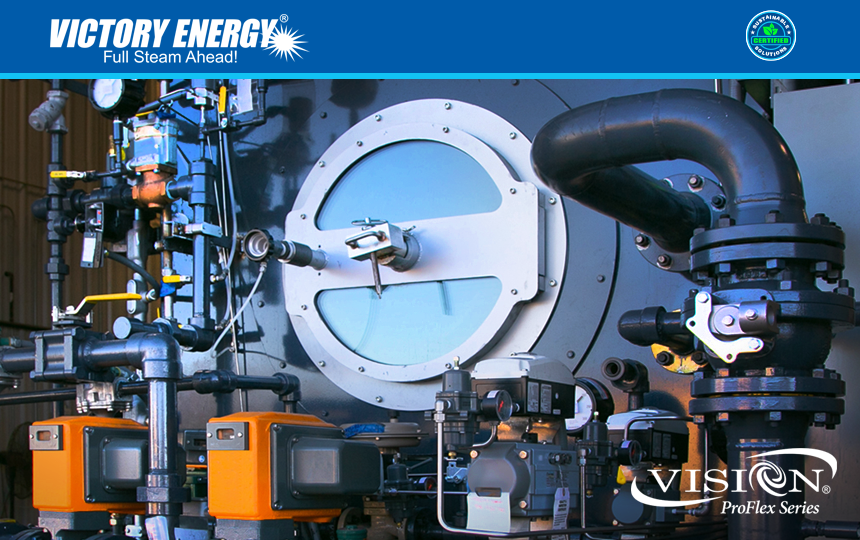

The large glass VISION ProFlex Series Door allows for a safe visual inspection during burner operation, providing an unprecedented level of visual insight into the core of the flame as well as the furnace.

Ideal for retrofit applications and new installments.

VISION ProFlex SERIES BURNER

- Robust Industrial Style Burner

- Engineered-To-Order

- 6 Sizes – 30 MMBtu/hr to 500 MMBtu/hr

- <9 ppm NOx – Gas

- <75 ppm NOx – Oil

- Low CO2, CO & VOC & PM

- Excellent Fuel Turn Down: 20:1 Gas & 8:1 Oil

- Heat Input Based on 70° F Air and 1000’ Elevation

- Gas and/or Oil Fuel Firing Capability

VISION ProFlex SERIES DOOR

- Large viewport

- Unparalleled visual inspection of the flame core

- Furnace Access door

SPARKMAX IGNITER

- Standard Equipment

- NFPA CLASS 1, 2 OR 3 GAS IGNITER

– Capacity ranges from 0,25 MMBtu/hr to 40 MMBtu/hr

– Standard to severe-duty environments

– 99% ignition rate in most applications

– Highly reliable ignition enhanced by quick Premix Combustion