Over the past five years, a confluence of environmental and economic conditions collided. This created the impetus for a totally vertically integrated burner and boiler system produced by one manufacturer.

The decades long approach of buying boiler and burner products from different suppliers was the de facto strategy that customers used when specifying solutions for their boiler room operations. Burner manufacturers and boiler providers worked within their separate silos of product expertise. While there was business engagement between burner and boiler entities to ensure that the components worked seamlessly together, companies never truly worked arm in arm to determine ways to increase efficiency and realize sustainability gains. Customers viewed buying burners and boilers from different manufacturers as the only game in town. They selected the best burner and boiler products for the application, but never gained the benefits of truly the “best system” for their application. That’s all changed today as environmental, societal and economic pressures have disrupted this old line thinking and way of purchasing burner and boiler systems. The game is changing which promotes the need for an integrated burner and boiler system provided by one OEM. It’s how Victory Energy is moving forward as a burner, boiler and heat recovery manufacturer.

Sustainability and Environmental Drivers

ESG initiatives from the C-Suite are being driven top down to the floor of the boiler room. Sustainability gains are realized through greater carbon reduction and energy efficiencies. This magic occurs when all the products work seamlessly together as one integrated solution. This is increasingly difficult to achieve when you’re dealing with multiple suppliers that don’t work together. Sustainability is an ongoing and never-ending initiative. Boilers and burners are critical components to achieve sustainability gains derived from reduced emissions, either through retrofit strategies or new boilers. Positive results are best achieved through an integrated burner and boiler configuration from one source.

Performance Metrics – Measuring the Impact

Who knows a boiler better than the company that builds it? This involves understanding the performance metrics of burners and boilers operating as one totally integrated unit. Intimately understanding how a burner operates in tandem with a boiler is paramount to achieving the best sustainability performance. It requires a steam test facility where boilers and burners are put through the rigors of real-time operation. This insight is applied to future product designs. That’s what happens at Victory Energy. It’s a natural evolution to have burners and boilers come from one supplier.

Availability and Warranty Assurances – Trust the OEM

It is often said that the best “ability” is availability. Since the start of the pandemic in the spring of 2020, supply chain disruptions have severely impacted manufacturers’ ability to meet product delivery covenants. This is especially true in product configurations that rely upon multiple manufacturers. It pushes back delivery dates and jeopardizes installation and start-up schedules. At Victory Energy, our ability to manufacture burners, boilers and many other critical components mitigates and eliminates these supply chain issues that show no signs of abating.

Warranty issues are always a sticky issue for manufacturers to resolve. This is especially true when a system includes several key manufacturers involved in the overall solution. It becomes a finger pointing exercise as to who’s to blame for the performance or lack thereof. Customers are often left to negotiate with several individual manufacturers. By utilizing a vertically integrated burner and boiler solution from one manufacturer, warranty issues are reduced as you deal with only one company that’s responsible for the entire system. You have peace of mind and confidence in any warranty or performance issues. There is implicit trust in a vertically integrated burner and boiler system.

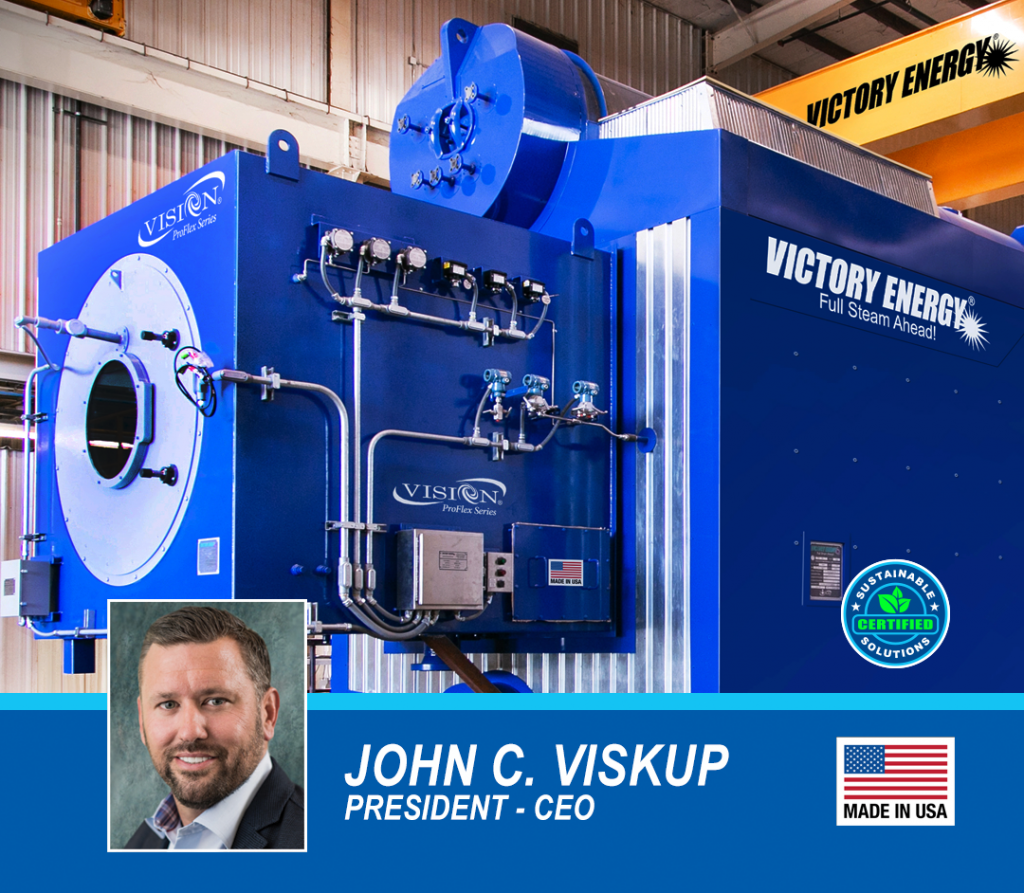

Vertical integration is the foundation upon which Victory Energy operates. Our goal is to continue to build and manufacture products under the roofs of our Cushing and Collinsville operations. Vertically integrating VISION burners with our extensive line of firetube, industrial boilers and heat recovery solutions is what customers have come to expect from us. It aligns with the desire of the market to deal with fewer manufacturers to ensure predictability and performance in their boiler room operations. It’s Full Steam Ahead with vertical integration of all product solutions at Victory Energy.